Monoblock Burners

HP Series Pneumatic Modulating Gas Burners

ECO 3000 HP GC 3

- Modulating operation,

- Mechanical, pneumatic or electronic modulating control option,

- Natural gas and LPG fuel usage,

- Operating possibility of 300 mbar and 21 mbar gas pressure,

- Wide thermal capacity range according to heat demand,

- Supply gas pressure control with minimum gas pressure switch,

- Combustion air control with air pressure switch,

- Sliding flange for different boiler types,

- Working at low noise levels with light aluminum alloy body,

- High combustion efficiency, uniform fuel and air mixing with original combustion head,

- Minimum friction losses throughout the body and combustion head,

- Flame control with ignition and ionization electrodes,

- Compact design with minimum maintenance,

- Easy access to all parts without dismantling the burner from the boiler,

- Direct ignition and optional pilot ignition,

- Environmentally friendly with low CO and NOx emissions.

- Working at low sound levels with to the specially designed burner body.

- Ease of maintenance with the hinged system without the need to separate the burner from the boiler,

| Burner Type | Capacity | Capacity | Natural Gas Consumption | Fan Motor Power | Main Supply | Gas Inlet Diameter | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Minimum kcal/h | Maximum kcal/h | Minimum kW | Maximum kW | Minimum Nm³/h | Maximum Nm³/h | kW | VAC | Gaz Valve | Gaz Inlet Diameter | |

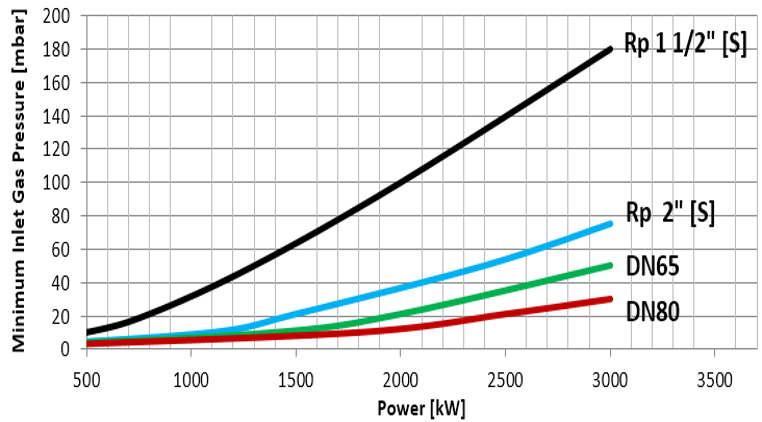

| ECO 3000 HP GC 3 1 1/2" -S | 516.00 | 2.580.000 | 600 | 3000 | 63 | 313 | 4 | 3N 400 | VGD 20.4011 | 1 1/2" |

| ECO 3000 HP GC 3 2" -S | VGD 20.5011 | 2" | ||||||||

| ECO 3000 HP GC 3 DN65 | VGD 40.065 | DN65 | ||||||||

| ECO 3000 HP GC 3 DN80 | VGD 40.080 | DN80 | ||||||||

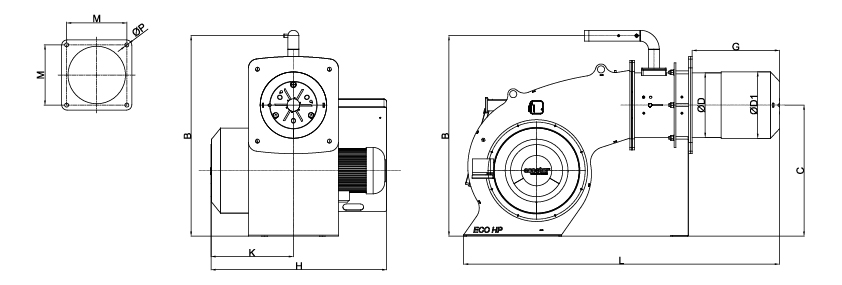

| * | L | Gmin | Gmax | H | K | B | C | ØP | M | ØD | ØD1 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ECO 3000 HP GC 3 | 1639 | 486 | 556 | 926 | 422 | 976 | 648 | 22 | 335 | 302 | 312 |

*All dimensions are in mm.

| Specifications | ECO 3000 HP GC 3 1 1/2" -S | ECO 3000 HP GC 3 2" -S | ECO 3000 HP GC 3 DN65 | ECO 3000 HP GC 3 DN80 |

|---|---|---|---|---|

| Control Type | O | O | O | O |

| Mechanical Modulating (21mbar) | ||||

| Mechanical Modulating (300mbar) | ||||

| Pneumatic Modulating (21mbar) | ||||

| Pneumatic Modulating (300mbar) | ||||

| Electronic Modulating (21mbar) | ||||

| Electronic Modulating (300mbar) | ||||

| Air Flow Rate Setting | SM | SM | SM | SM |

| Adjustable Flame Tube Extension | ||||

| Gas Valve | ||||

| Minimum Gas Processore | ||||

| Maximum Gas Processore | ||||

| Air Processore | ||||

| Flame Control | İO | İO | İO | İO |

| Ignition | DA | DA | DA | DA |

| VPS Gas Leakage Detector | ||||

| Sliding Boiler Connection Flange | ||||

| Service Hinge | ||||

| 7 Pin Power Supply and First Stage Socket | ||||

| 7 Pin Second Stage Connection Socket | ||||

| Compatible with TS EN 676+A2 ve 2016/426/EC GAR | ||||

| Electrical Protection Class | IP54 | IP54 | IP54 | IP54 |

:Not Included/N/A

:Optional

:Included/Available

1K:1 Stage

2K:2 Stage

O: Modulating

M: Manual

SM: Servomotor

İO: Ionization

F:Photocell

DA: Direct Ignition

PA: Pilot Ignition