Products

Industrial Burners

Energy efficiency and environmentally friendly technologies are becoming increasingly important in the energy sector and industrial systems. In this context, industrial burners play a significant role in energy production and heating systems. Ecostar is a leading provider of industrial burners that promote the use of renewable energy and energy savings in the industry.

Ecostar Industrial Burner Models

Ecostar offers a wide range of products by dividing its industrial burners into various sub-categories. Ecostar’s industrial burner product range can be categorized into 6 main groups, including burner system equipment:

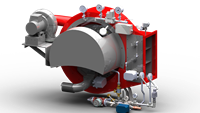

Ecostar Industrial Burners consist of ECO, DSE, DIB, MIB, GIB series burners, process burners including FPB, High Speed Burners, Gazoram, Ecoflue, duct burners, recuperative burners, furnace burners, coal burners, immersion burners and special burners and hot air generators. Industrial burners can operate with natural gas, LPG, heavy oil, light oil and combined fuels. Thanks to its large power capacity and high combustion efficiency, it can be used in start-up applications in industrial boilers, steam boilers, hot water boilers, hot oil boilers, industrial boilers, hot air generators, rotary dryers (such as asphalt plant), fluidized bed and grate boilers. It has a wide range of important uses in the industry, including drying applications such as asphalt plant burner, industrial furnace applications, cement plants, paper mills, sugar factories, heat treatment furnaces, melting pots, ceramic industry baking processes, textile and wood industry, food, soil, chemistry, fertilizer, metal industry, paper and packaging industry, biomass power plants, thermal power plants.

These industrial burners are extensive preferred in industries such as drying applications like asphalt plant burners, industrial oven applications, cement plants, paper mills, sugar mills, heat treatment furnaces, melting pots, ceramic industry firing processes, textile and wood industry, food, clay, chemical, fertilizer, metal industry, paper and packaging industry, biomass power plants and thermal power plants.

These high-efficiency industrial burner systems are of great importance in achieving energy savings and cost reduction. The ECO, MIB, DIB, DSE, GIB, and CIB series have monoblock and duoblock body structures and can operate with natural gas, LPG, heavy oil, light oil and combined fuels. These models, which can be produced for specific applications, can be easily used in hot water boilers, steam boilers, hot water boilers, steam boilers, hot oil boilers, fluidized bed boilers and hot air generators in line with the needs. They can also provide superior efficiency in drying applications, asphalt plants, and startup applications.

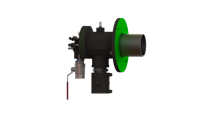

Process burners, such as FPB process burners and Gazoram burners, are used in industrial processes that require continuous heating and energy. Examples of these applications include hot air generators, industrial furnaces, melting pots in heavy industries, ram machines used in the textile sector, and drying processes and high-temperature baking in industries such as metal, food, ceramics, and paint. Ecostar process burners can operate with natural gas, LPG, heavy oil, light oil and combined fuels.

Hot air generators, another product in the Ecostar product range, can operate with natural gas, heavy oil, light oil and dual fuels and provide services in a wide temperature range according to process requirements. They can be effectively used in various applications such as the soil industry, air conditioning industry, fertilizer industry, sugar industry, paper industry, metal industry, drying furnaces, cement industry applications. Systems like industrial burners and hot air generators provided by Ecostar offer efficient and environmentally friendly solutions in energy production and heating processes.

For the product range regarding Start-Up burners for biomass power plants, the thermal energy needed for boilers is generated through the combustion of natural gas, diesel, fuel oil, biogas, or LPG, based on the specific requirements of our customers. Our ECOSTAR burners have become the preferred choice for numerous prominent biomass power plants across Turkey. Moreover, ECOSTAR offers a comprehensive range of auxiliary system equipment for these plants, including fuel stations required for burner combustion systems and the selection and provision of burner control equipment that can seamlessly integrate with existing DCS/PLC systems.

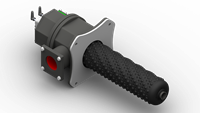

In addition to industrial burners, Ecostar also offers solutions to the industry with burner system equipment such as diesel oil stations, fuel oil stations, electronic air-fuel control, O2-CO combustion management systems, fan speed control, and control automation systems. This encourages the adoption of both efficient and environmentally friendly technologies in energy production and consumption processes. As a solution-oriented company, Ecostar is committed to serve as a reliable partner for our clients, offering engineering expertise, equipment procurement, and project contracting support across various industries.