Industrial Burners

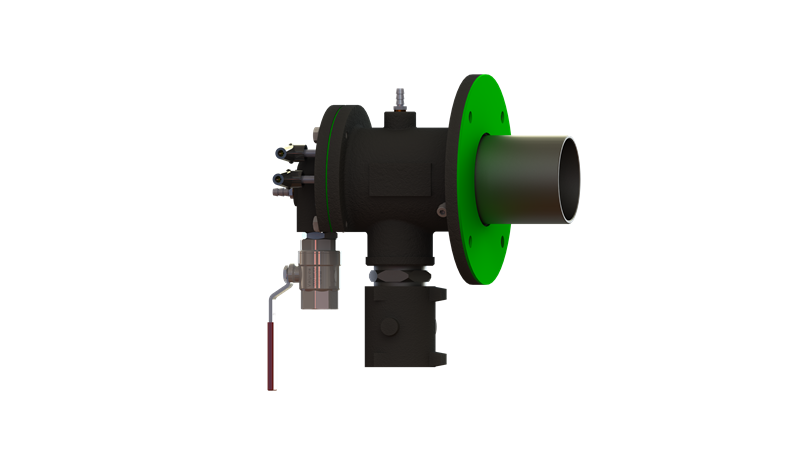

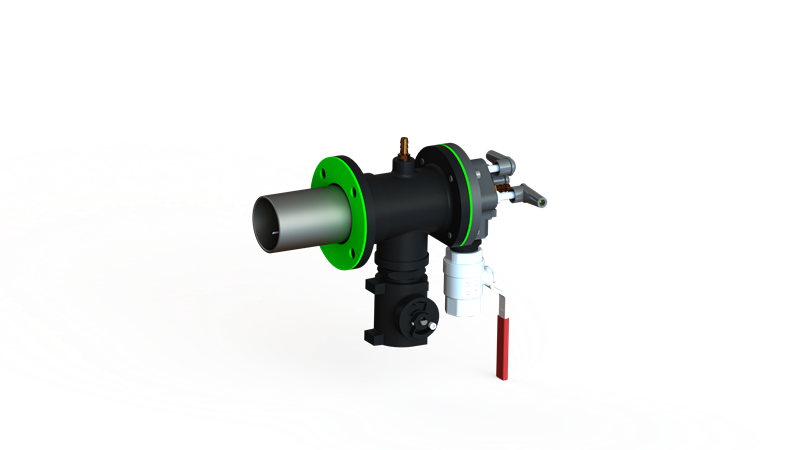

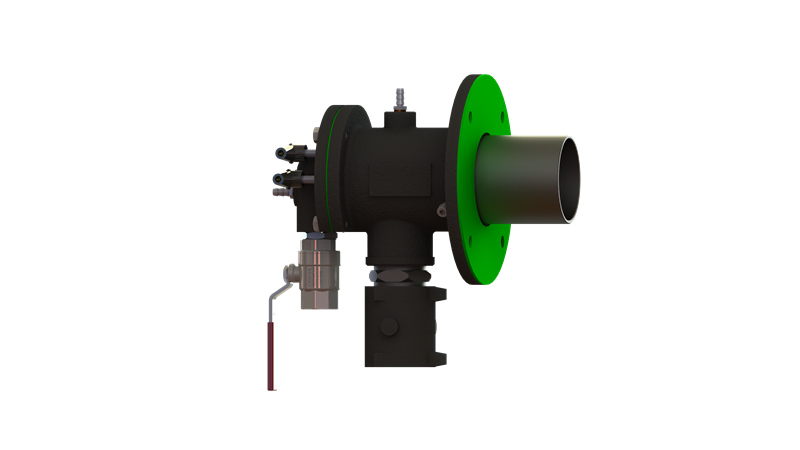

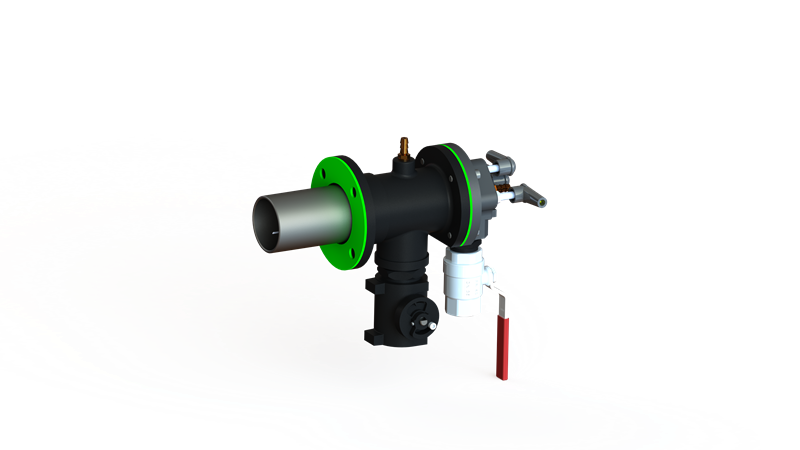

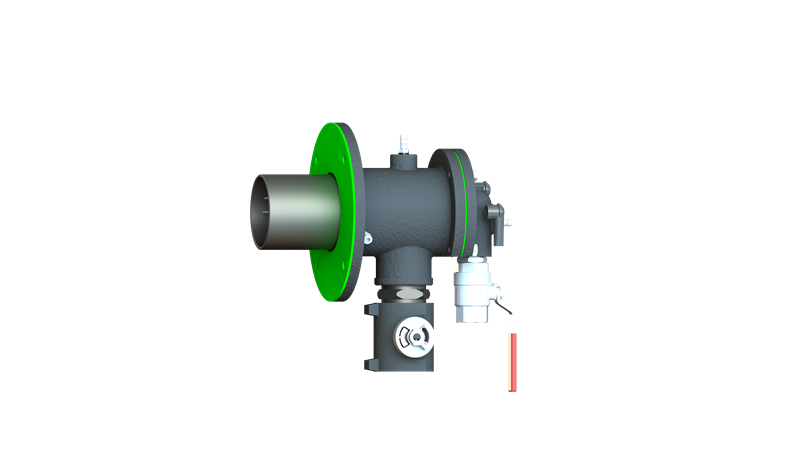

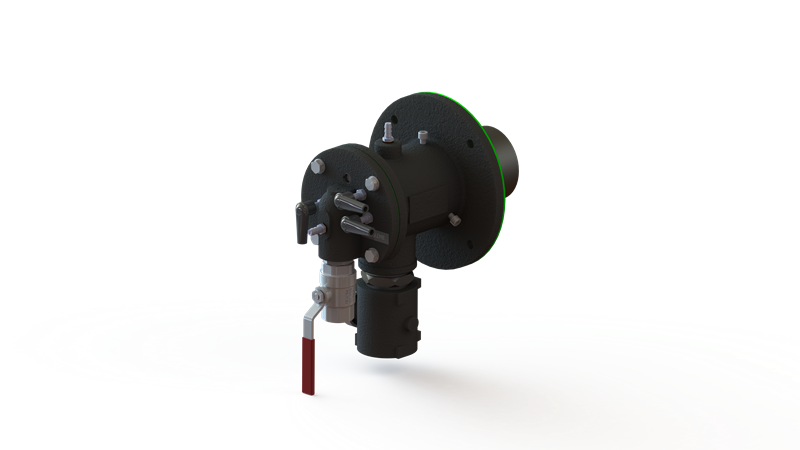

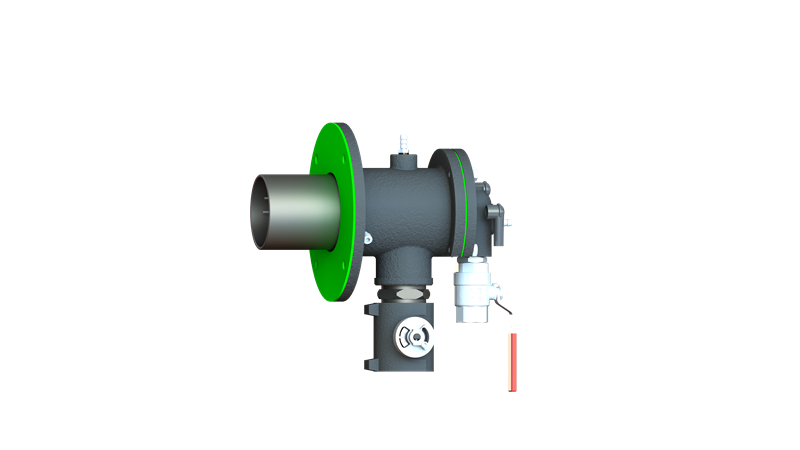

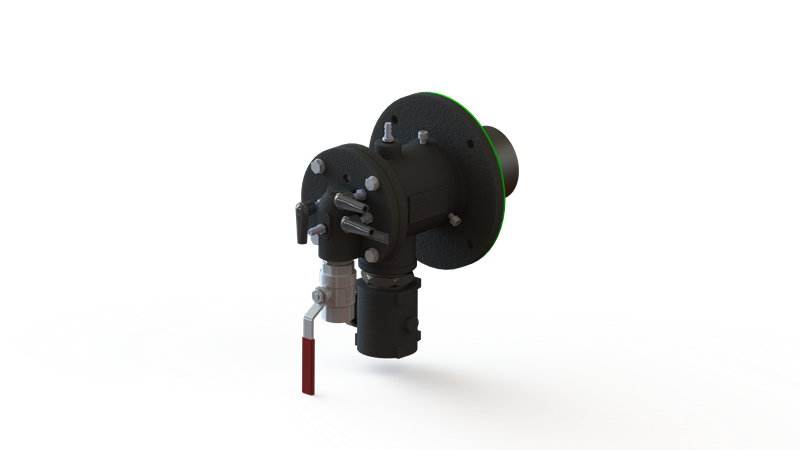

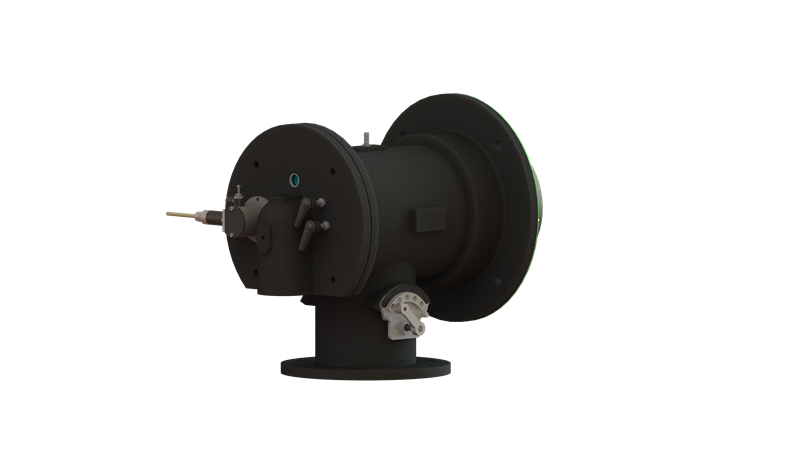

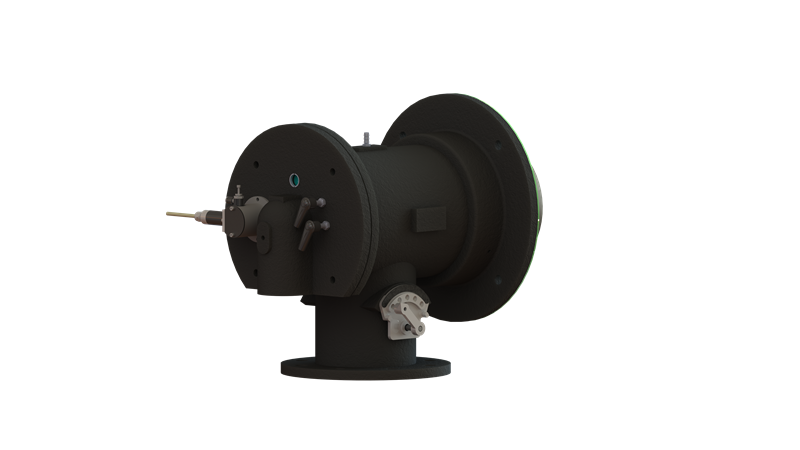

FPB

FPB 40

ECOSTAR FPB series Process Burners are compatible even with heavy industry applications thanks to its superior design. Easy connection with the connecting flange and the optional flame tube length allow easy adaptation to the rendered systems. System-specific designed control and command panels meet the requirements of single and multi-zone control systems.

Specifications

- 4 - 5800 kW wide capacity range

- Operation with Natural Gas, LPG, Light Oil and Heavy Oil

- Flame tube and turbulator made of high temperature resistant Chromium-Nickel material

- High efficiency and smooth operation in applications with high temperatures

- Single stage, two stage, manually modulating, mechanically modulating, pneumatically modulating (Natural gas) and electronically modulating control options; depending on the needs and demand

- Single and multi-zone control systems

- Control panel attached to, or detached from, the body, depending on the application’s requirement

- Direct or pilot ignition option (pilot ignition is optional for certain models.)

- Ionization or photocell flame control (Photocell flame control is optional for certain models.)

- Easy assembly and disassembly thanks to its design

- Easy operation and maintenance

- Different installation options that allow compatibility with various industrial applications

- Optional long flame tube option which allows adaptation to new and modernized legacy applications.

Areas of Application

- It is used in furnaces and salt baths where treatment processes are carried out by annealing, recrystallization, normalization, carburization, hardening,

- In furnaces with crucible and similar ones where alloys like aluminum, magnesium and copper are melted down,

- In dye cabinets where dyed metal products are kiln-dried in dyeing sector,

- In indirect hot air gas generators manufactured to dry various foodstuff,

- In cabin, tunnel and cart type furnaces that are used in firing similar materials like porcelain and ceramic.

| Type | Capacity | Capacity | Natural Gas Consumption | LPG Consumption | Light Oil Consumption | Heavy Oil Consumption | FAN | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Minimum kcal/h | Maximum kcal/h | Minimum kW | Maximum kW | Minimum Nm³/h | Maximum Nm³/h | Minimum Nm³/h | Maximum Nm³/h | Minimum kg/h | Maximum kg/h | FLOW Nm³/h |

|

| FPB 40 | 8.000 | 40.000 | 9,3 | 46,5 | 1,0 | 4,8 | 0,4 | 1,8 | - | - | 70 |

| Body | A | G | ØD | ØH | ØDG | ØM | ØP | |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | - | - | mm | mm | ||

| FPB 40 | Casting | 250 | 100 | 48,3 | R 3/4" | R 3/8" | 90 | 9 |